Custom

Mteck Cranes BV knows that every client has different specific demands for their machines. We construct the best custom-made machines for every application. The possibilities are endless.

Loadmoment capacity

The chassis of an Mteck crane is determined by multiplying work load by work distance. For example: hoisting 25 mT at a distance of 16 meters requires an Mteck400 chassis (25 * 16 = 400). The last two digits specify the winch size. An Mteck425 is an Mteck400 with hoist and closing winches that put out 25mT of pulling force. Drag the slider below to see some cranes of different sizes.

| Max load | Dredging 10 mT – Hoisting 20 mT |

|---|---|

| Hoist line pull | 10 mT |

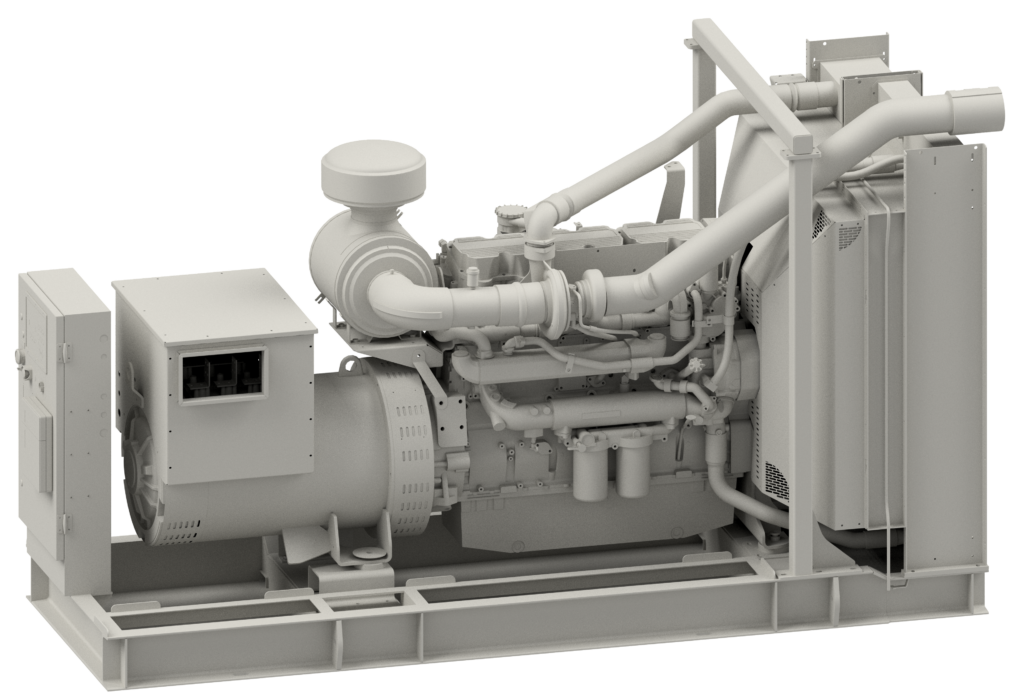

| Generator power | 400 HP |

| Machine weight | 55 mT |

| Trim | N/A |

| Heel | N/A |

| Max load | Dredging 12 mT – Hoisting 24 mT |

|---|---|

| Hoist line pull | 12 mT |

| Generator power | 450 kVA |

| Machine weight | 72 mT |

| Max load | Dredging 16 mT – Hoisting 32 mT |

|---|---|

| Hoist line pull | 18 mT |

| Generator power | 650 kVA |

| Max load | Dredging 25 mT – Hoisting 50 mT |

|---|---|

| Hoist line pull | 25 mT |

| Generator power | 790 kVA |

| Max load | 25 mT |

|---|---|

| Hoist line pull | 25 mT |

| Generator power | 670 kVA |

| Machine weight | 288 mT |

| Max load | Dredging 75 mT – Hoisting 150 mT |

|---|---|

| Hoist line pull | 75 mT |

| Generator power | 2100 kVA |

| Machine weight | 387 mT |

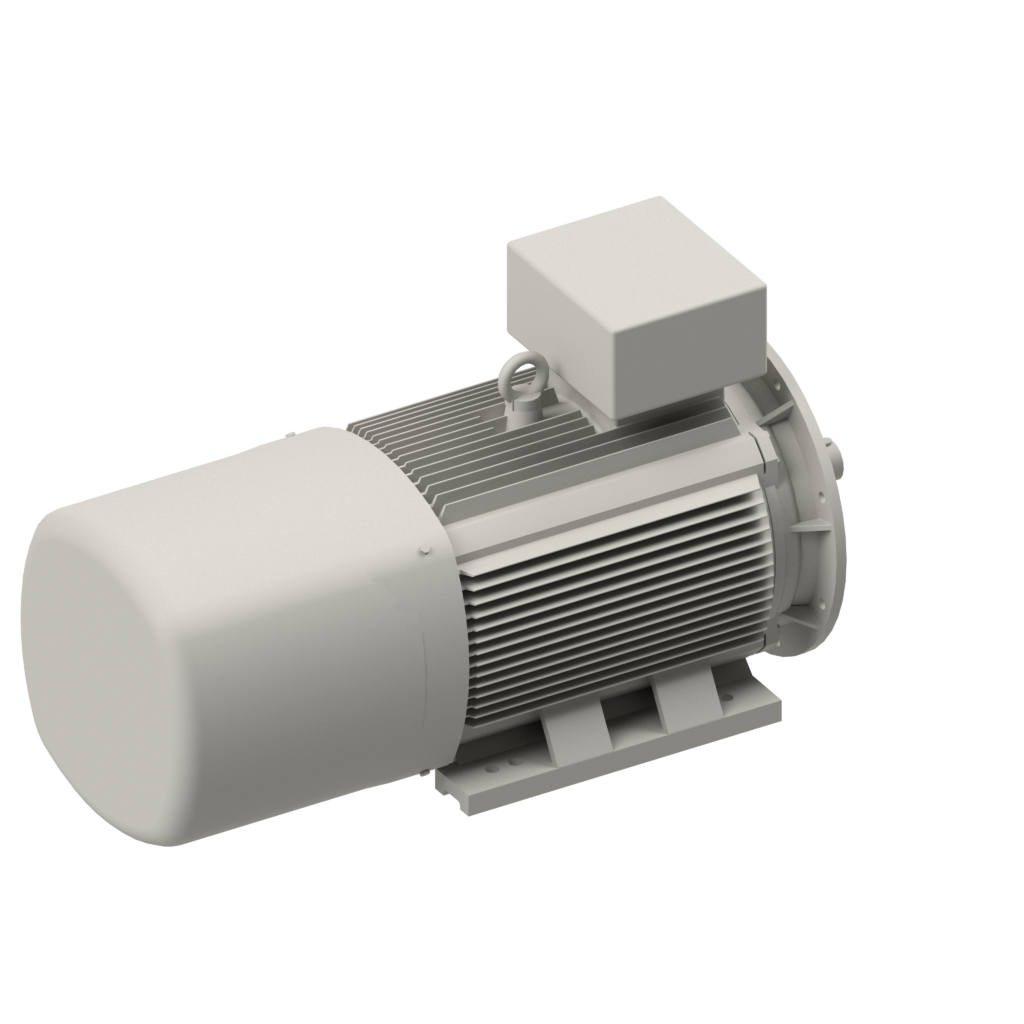

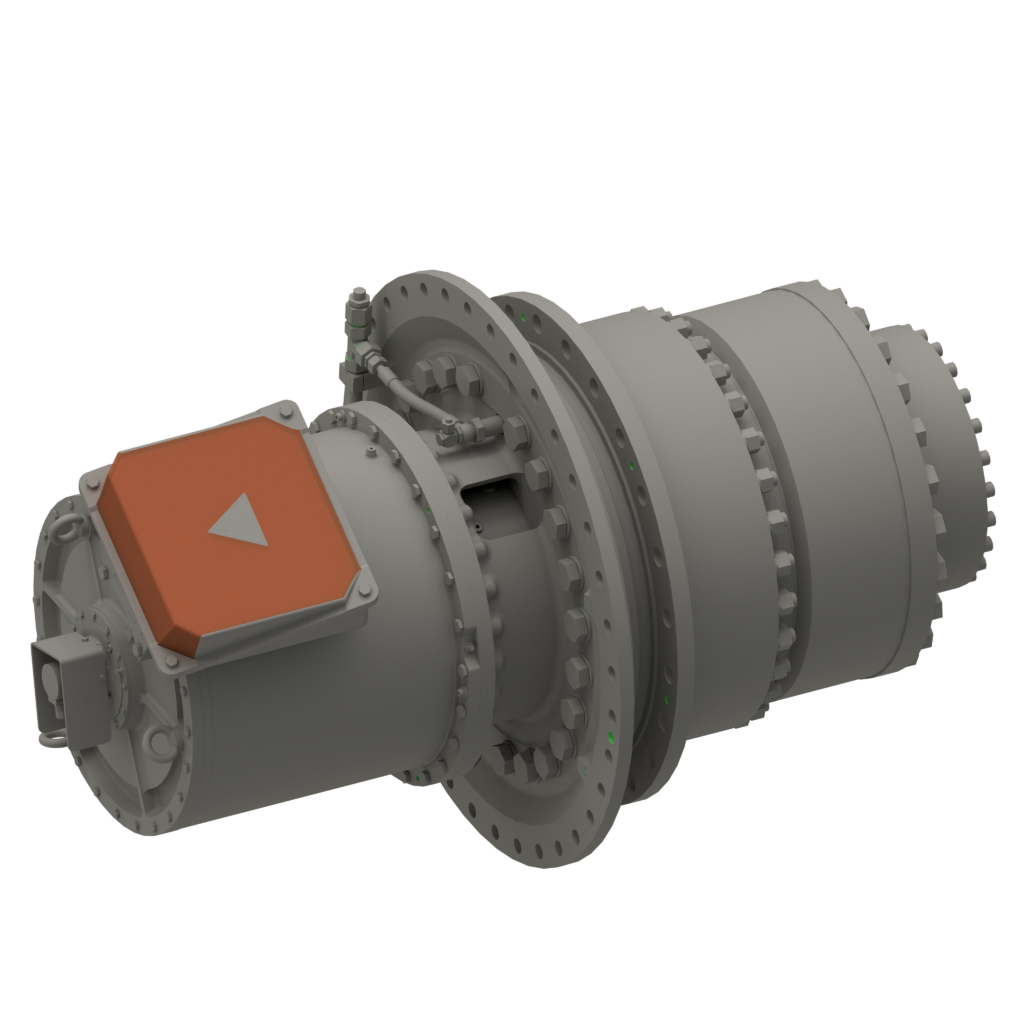

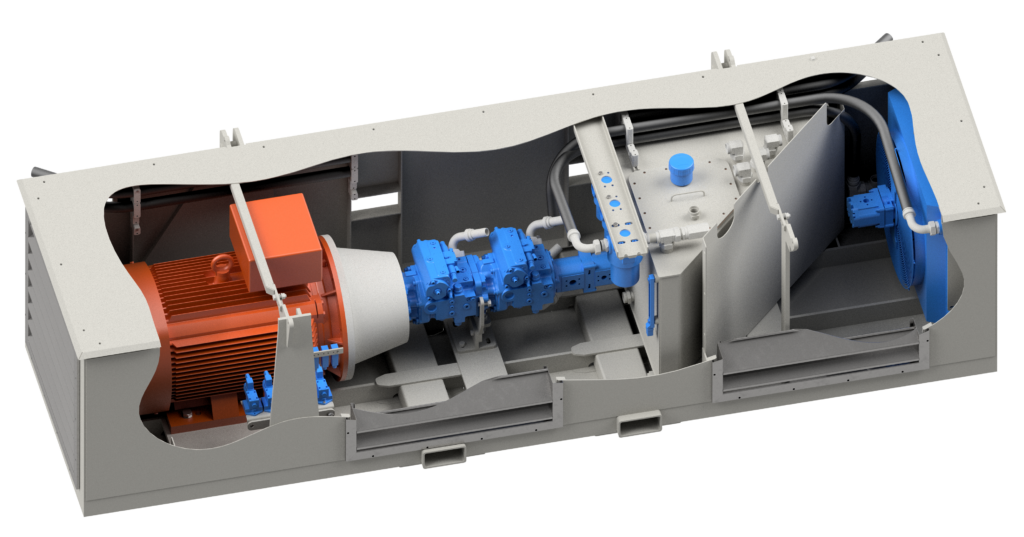

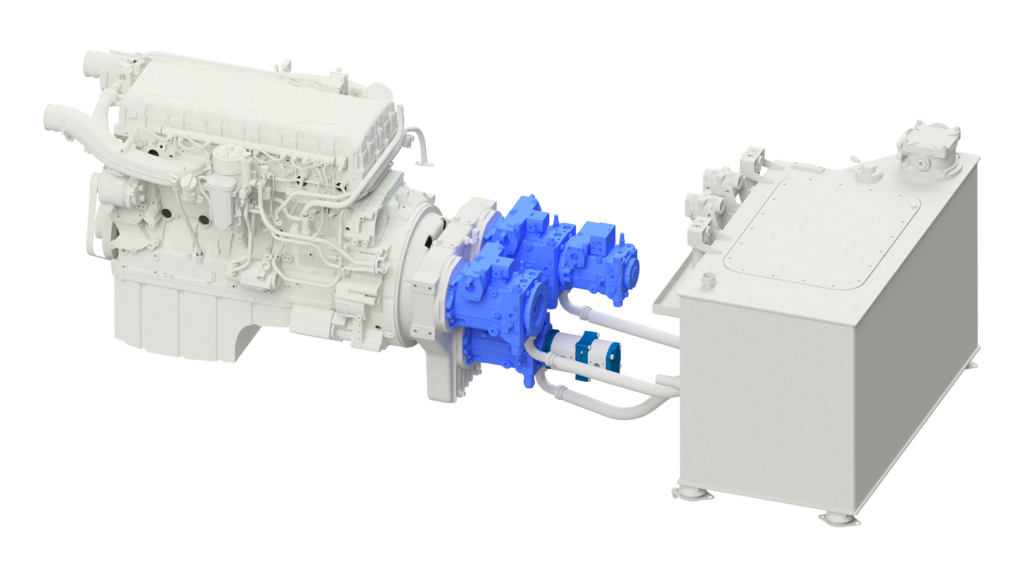

Drivetrain

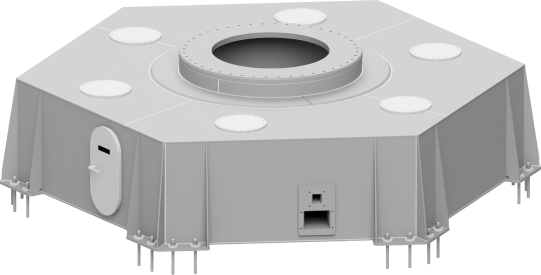

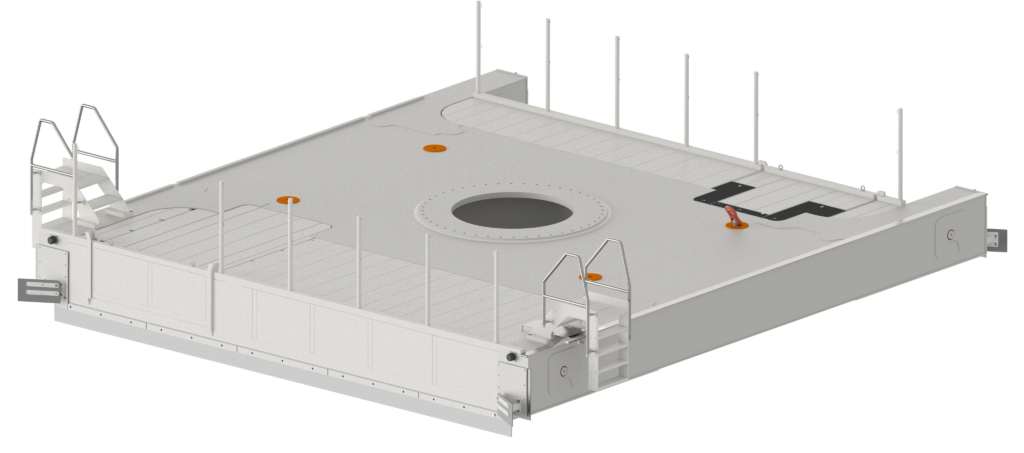

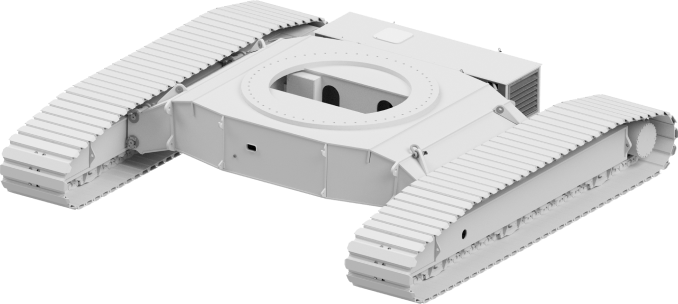

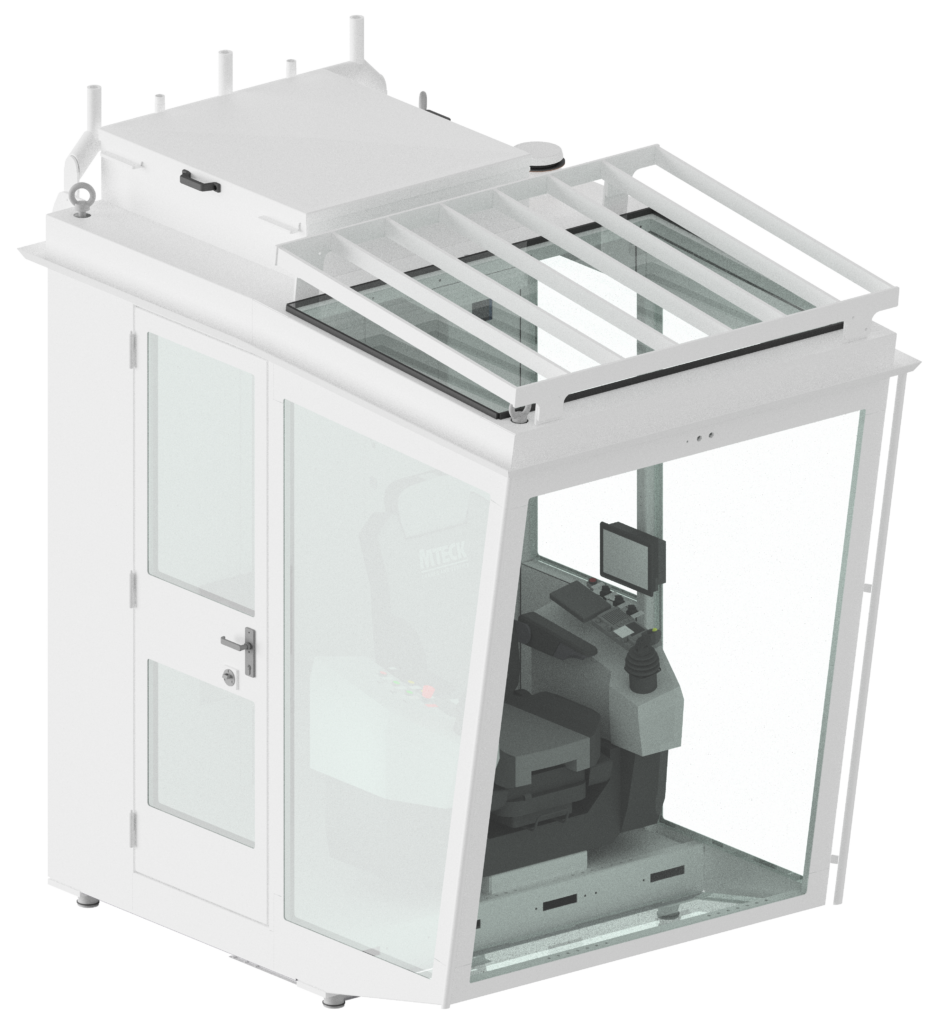

Crane mount

Designed for comfort, wherever

Our cabins are designed and built to meet all of your expections. The cabin itself is incredibly spacious, ergonomic, and comes with central air conditioning and heating. A compact alternative is also available.

Remote service 24/7 GPS analyses

At the moment our mechanics perform maintenance to dredge cranes all around the world. With a professional attitude and a down-to-earth mentality they identify problems before they actually occur. This prevents wear and tear which may lead to downtime.

Consumption / cycle

The drive train of an Mteck crane is fully electrically driven, that’s why we can achieve an efficiency of 97%. This efficiency can be converted 1 to 1 into energy consumption (gasoil if running from a generator, or Kwh if the installation is powered from the grid)

Average maintenance costs

One of the most expensive cost of an actual repair is the loss of operating income that results when a crane is out of service. Mteck provides fully electric crane systems that will have an operational downtime of 0,3% on a life expectancy of 40 years before a complete overhaul.

Legal, norms and certificates

Engineered by the best

Mteck cranes are engineered and built according to european crane standards.

If needed, the engineering and build can be done according to the rules of classification companies from the shipping and offshore industry, for example Lloyds and Bureau Veritas.

The Mteck cranes will be classified in the highest class of use, wich results in a durable crane system that will prove its services for a long time without problems and a low downtime.

This applies to the crane structure as well as to the crane mounted components like gearboxes, motors, bearings, pins and slewing ring.